2016 – 2019, funded by DAAD

The Indian and the German society are challenged by the necessity of a sustainable development. Overcoming these challenges requires educated professionals.

Nowadays, the engineering education in Indian universities has a huge potential in combining scientific theoretical education with practical experience. To ease the transition of graduates into the job market, it is advisable to have practical education with industrial context in universities. Especially in reference to management and performing abilities in industrial-like manufacturing environments, shortcomings in current university education have to be compensated. In this context, the idea to adopt the Experience Lab of the IWF to the learning environment of BITS Pilani was an ideal extension.

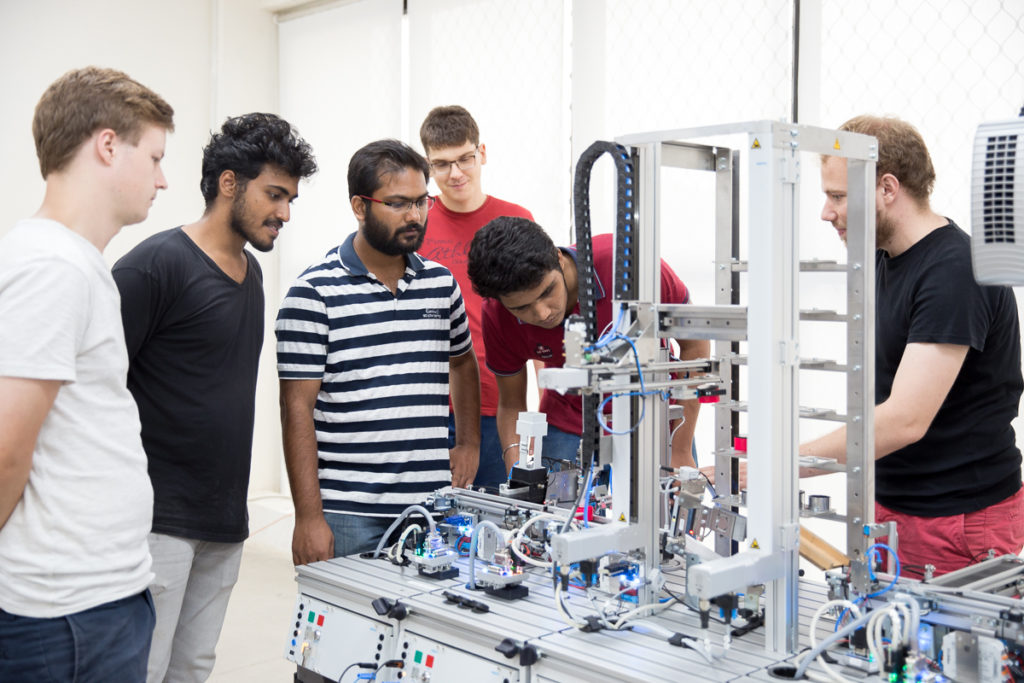

The IWF Experience Lab reproduces the most important manufacturing processes in a smaller scale, which makes it possible for students to work in a safe and industrial-like factory environment. Each module of the Experience Lab reproduces one relevant industrial manufacturing process. The used control systems are the same as in industrial machines and they use the same types of power (electricity, compressed air, and heat), but in a safe scale. In this way students can use the methods they have learned in an industrial-like factory environment. Together with the German practice partner Festo Didactic SE, which supplies the educational infrastructure, the four year DAAD project “Joint Indo-German Experience Lab” (JInGEL) was started in 2016. The goal of this project is to adapt the experiences of engineering education in the Experience Lab at TU Braunschweig to the Indian university environment. As reference project for further Indian universities and further education institutions, the concept will be introduced at BITS Pilani.

The IWF Experience Lab reproduces the most important manufacturing processes in a smaller scale, which makes it possible for students to work in a safe and industrial-like factory environment. Each module of the Experience Lab reproduces one relevant industrial manufacturing process. The used control systems are the same as in industrial machines and they use the same types of power (electricity, compressed air, and heat), but in a safe scale. In this way students can use the methods they have learned in an industrial-like factory environment. Together with the German practice partner Festo Didactic SE, which supplies the educational infrastructure, the four year DAAD project “Joint Indo-German Experience Lab” (JInGEL) was started in 2016. The goal of this project is to adapt the experiences of engineering education in the Experience Lab at TU Braunschweig to the Indian university environment. As reference project for further Indian universities and further education institutions, the concept will be introduced at BITS Pilani.

Some of the students who took part in the exchange programme

Stay in Braunschweig, Report by Rishi Kumar (June 16, 2020) Posted in: Exchange, Exchange to Germany

Stay in Braunschweig, Report by Rishi Kumar (June 16, 2020) Posted in: Exchange, Exchange to Germany Stay in Braunschweig, Report by Abhineet Nigam (December 12, 2019) Posted in: Exchange, Exchange to Germany

Stay in Braunschweig, Report by Abhineet Nigam (December 12, 2019) Posted in: Exchange, Exchange to Germany Stay in Braunschweig, Report by Sourojit Saha (December 7, 2019) Posted in: Exchange, Exchange to Germany, News

Stay in Braunschweig, Report by Sourojit Saha (December 7, 2019) Posted in: Exchange, Exchange to Germany, News Stay in Braunschweig, Report by Lokesh Kumar Patel (June 23, 2019) Posted in: Exchange, Exchange to Germany

Stay in Braunschweig, Report by Lokesh Kumar Patel (June 23, 2019) Posted in: Exchange, Exchange to Germany Stay in Braunschweig, Report by Siddartha Idukuda (June 16, 2019) Posted in: Exchange, Exchange to Germany

Stay in Braunschweig, Report by Siddartha Idukuda (June 16, 2019) Posted in: Exchange, Exchange to Germany Stay in Pilani, Report by Yannick Pfisterer (December 21, 2018) Posted in: Exchange, Exchange to India

Stay in Pilani, Report by Yannick Pfisterer (December 21, 2018) Posted in: Exchange, Exchange to India Stay in Pilani, Report by Kurosh Nazerian (December 14, 2018) Posted in: Exchange, Exchange to India

Stay in Pilani, Report by Kurosh Nazerian (December 14, 2018) Posted in: Exchange, Exchange to India Stay in Braunschweig, Report by Atul Jala (December 13, 2018) Posted in: Exchange, Exchange to Germany

Stay in Braunschweig, Report by Atul Jala (December 13, 2018) Posted in: Exchange, Exchange to Germany Stay in Braunschweig, Report by Manpreet Singh (December 11, 2018) Posted in: Exchange, Exchange to Germany

Stay in Braunschweig, Report by Manpreet Singh (December 11, 2018) Posted in: Exchange, Exchange to Germany Stay in Pilani, Report by Maximilian Rolinck (December 1, 2018) Posted in: Exchange, Exchange to India

Stay in Pilani, Report by Maximilian Rolinck (December 1, 2018) Posted in: Exchange, Exchange to India Stay in Braunschweig, Report by Parikshit Agrawal & Mohit Jagetiya (June 23, 2018) Posted in: Exchange, Exchange to Germany

Stay in Braunschweig, Report by Parikshit Agrawal & Mohit Jagetiya (June 23, 2018) Posted in: Exchange, Exchange to Germany Stay in Pilani, Report by Jan-Philipp Kues (December 30, 2017) Posted in: Exchange, Exchange to India

Stay in Pilani, Report by Jan-Philipp Kues (December 30, 2017) Posted in: Exchange, Exchange to India Stay in Pilani, Report by Jannik Lücking (September 29, 2017) Posted in: Exchange, Exchange to India

Stay in Pilani, Report by Jannik Lücking (September 29, 2017) Posted in: Exchange, Exchange to India